In recent years, the industrial automation sector has witnessed significant advancements in the development and application of control systems. Among these innovations, the Pulse Solenoid Valve stands out as a pivotal component in various industries, from manufacturing to process control. As the demand for precision, efficiency, and automation continues to grow, the Pulse Solenoid Valve is becoming indispensable for a wide range of applications, including fluid control, air pressure regulation, and material handling.

What is a Pulse Solenoid Valve?

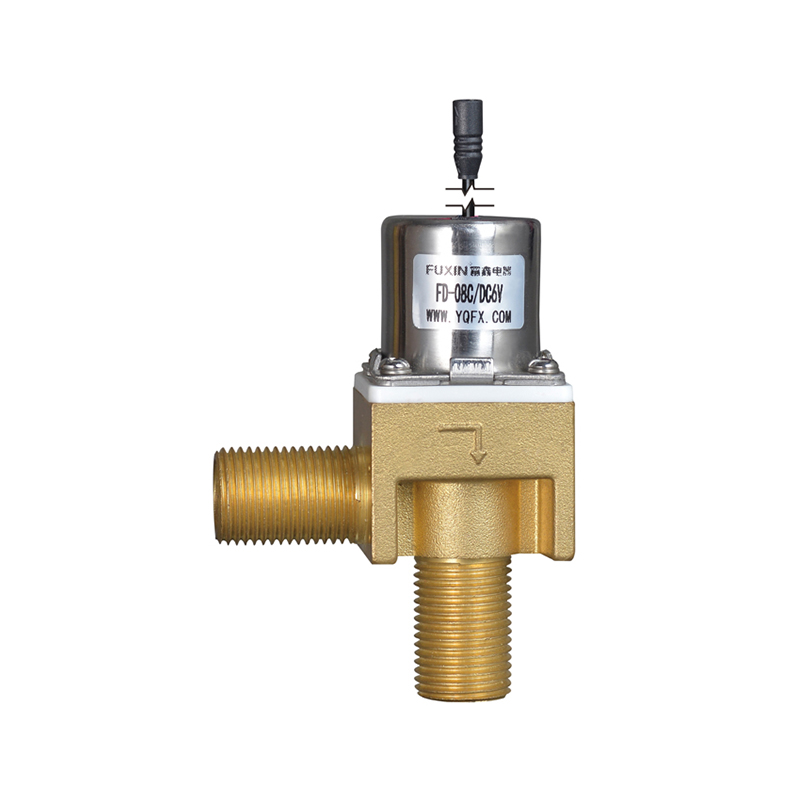

A Pulse Solenoid Valve is an electromechanical valve that controls the flow of liquids or gases by using electrical pulses to activate or deactivate the valve. Typically used in systems requiring precise control over flow rates or pressure, these valves are triggered by an electrical signal, which causes the valve’s solenoid coil to either open or close. The "pulse" refers to the brief, controlled bursts of electrical current that prompt the valve's movement, enabling it to operate in short, intermittent cycles.

One of the key features of the Pulse Solenoid Valve is its ability to provide quick, accurate, and repeatable control of fluids and gases. The design of the valve allows it to handle high-frequency switching, making it ideal for applications that require fast response times and reliable operation over extended periods.

The Growing Importance of Pulse Solenoid Valves

Pulse solenoid valves have gained increasing prominence in industrial sectors due to their performance in regulating fluids, gases, and air within automation systems. They offer several advantages over traditional valve types, including:

Precision Control

The Pulse Solenoid Valve provides precise control over the flow of fluids or gases. This precision is critical in applications where accurate timing and flow rates are necessary, such as in air compressor systems, pneumatic tools, and industrial process controls. By receiving electrical pulses at specific intervals, the valve can manage small increments of flow, ensuring that processes operate within the desired parameters.

Increased Efficiency

With the ability to operate on a pulsed signal, these valves can cycle rapidly, allowing for greater energy efficiency. In applications such as water treatment plants, where large volumes of liquid need to be pumped or filtered, the Pulse Solenoid Valve can ensure that only the exact amount of fluid is processed at the required time. This reduces energy consumption by preventing excessive or wasteful flow, contributing to both operational and environmental efficiency.

Fast Response Time

The Pulse Solenoid Valve can open and close almost instantaneously, providing rapid adjustments to fluid or gas flow. This feature is especially beneficial in industries where real-time control is necessary, such as in the food and beverage, automotive, and pharmaceutical sectors. In these industries, even slight delays in fluid control can to system inefficiencies, equipment damage, or compromised product quality.

Compact Design

Pulse solenoid valves are typically smaller and more compact than traditional valves, making them ideal for applications with limited space. Their small size and light weight allow them to be integrated into tight spaces or within portable equipment, making them an ideal choice for various industrial applications where space is a premium.

Durability and Reliability

Another advantage of the Pulse Solenoid Valve is its reliability in high-cycle applications. These valves are designed to withstand frequent activation and deactivation, making them ideal for use in environments where equipment must function continuously or for extended periods. Whether it’s controlling air pressure in pneumatic systems or regulating water flow in filtration units, pulse solenoid valves are engineered to deliver consistent performance even under harsh conditions.

Key Applications of Pulse Solenoid Valves

Pulse solenoid valves are used in a variety of industrial applications, owing to their ability to provide precision, efficiency, and durability. Some key sectors where these valves are commonly used include:

Industrial Automation and Process Control

In manufacturing environments, the Pulse Solenoid Valve plays a critical role in process control, regulating the flow of air, gas, or liquid through systems. In automated assembly lines, for example, these valves help control pneumatic actuators and robotic arms, ensuring that machinery operates efficiently and with minimal downtime.

Water Treatment

Water treatment plants often utilize pulse solenoid valves to manage the flow of water through filtration, disinfection, and chemical dosing systems. By precisely controlling the timing and flow of water and chemicals, these valves help optimize the treatment process, ensuring high-quality water output while minimizing waste.

EN

EN English

English Español

Español