In the world of modern plumbing, innovation continues to drive the development of smarter and more efficient systems. Among these advancements, the Plastic Latching Water Solenoid Valve stands out as a key player, revolutionizing how water flow is controlled in various applications. This lightweight and cost-effective valve offers numerous benefits, making it an attractive choice for a wide range of settings, from residential homes to large-scale commercial operations.

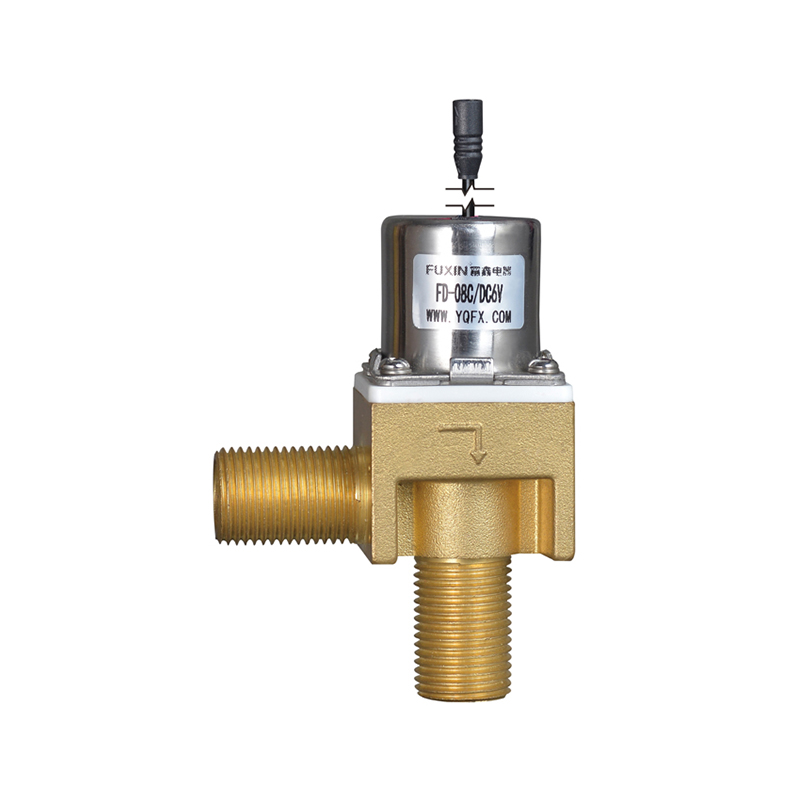

The Plastic Latching Water Solenoid Valve is a crucial component used in systems that require precise control of water flow. Unlike traditional solenoid valves, which often require a continuous electrical current to maintain their open or closed state, latching valves use a brief electrical pulse to switch between positions. This feature not only conserves energy but also reduces wear on the valve, extending its operational life.

Made from durable plastic materials, these valves are resistant to corrosion and chemical damage, making them ideal for use in environments where metal valves might degrade over time. The lightweight nature of plastic also simplifies installation and reduces the overall weight of plumbing systems, which can be particularly beneficial in complex or large-scale setups.

The Plastic Latching Water Solenoid Valve is widely used in various applications, including irrigation systems, water purification units, and industrial processes. Its ability to precisely control water flow makes it invaluable in scenarios where accurate water distribution is critical, such as in agriculture or manufacturing.

One of the significant advantages of using a Plastic Latching Water Solenoid Valve is energy efficiency. Since these valves only require power when switching states, they consume significantly less electricity than traditional solenoid valves. This energy-saving feature not only lowers operational costs but also aligns with global efforts to reduce energy consumption and minimize environmental impact.

In addition to energy efficiency, the durability of plastic valves offers long-term cost savings. The resistance to corrosion and chemical damage ensures a longer lifespan, reducing the need for frequent replacements and maintenance. This durability is particularly important in industrial settings where downtime for repairs can be costly.

The market for Plastic Latching Water Solenoid Valves has seen substantial growth in recent years, driven by increasing demand for efficient and reliable water management solutions. As industries and households alike seek to reduce water wastage and optimize resource use, the adoption of advanced valve technologies has become more prevalent.

In the agricultural sector, for example, these valves play a crucial role in drip irrigation systems, where precise water control is essential for crop health and yield optimization. The use of Plastic Latching Water Solenoid Valves in such systems helps farmers manage water resources more effectively, to better crop outcomes and more sustainable farming practices.

The industrial sector also benefits from these valves, particularly in processes that require controlled water flow, such as cooling systems and chemical manufacturing. The reliability and durability of plastic valves make them an choice for these demanding environments, where maintaining consistent water flow is crucial.

Despite the many benefits, there are challenges associated with the use of Plastic Latching Water Solenoid Valves. One primary concern is the potential for plastic degradation under temperatures or exposure to harsh chemicals. While many plastics are engineered to withstand such conditions, there is always a risk of material fatigue or failure over time.

To mitigate these risks, manufacturers often incorporate advanced plastic compounds or protective coatings that enhance the durability and chemical resistance of the valves. However, it is essential for users to consider the specific environmental conditions and choose the appropriate valve materials accordingly.

Looking ahead, the demand for Plastic Latching Water Solenoid Valves is expected to continue growing, driven by advancements in smart technology and increasing awareness of water conservation. The integration of sensors and IoT technology into valve systems could further enhance their functionality, allowing for remote monitoring and control. This capability would provide users with real-time data on water usage and system performance, enabling more efficient management of water resources.

EN

EN English

English Español

Español