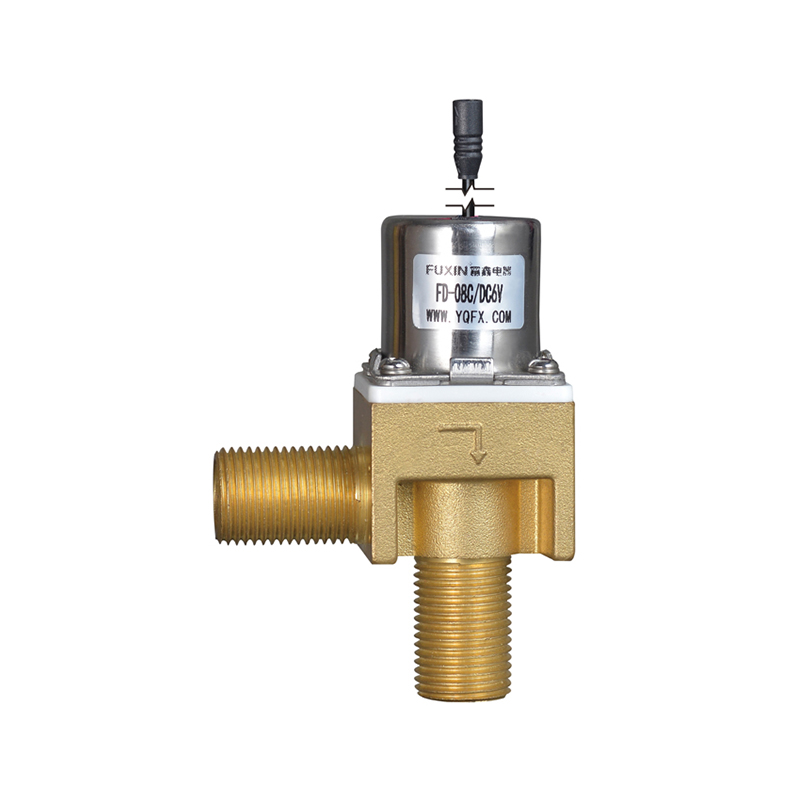

In the ever-evolving world of industrial automation and control systems, the DC Low Voltage Electrical Magnetic Solenoid Valve is emerging as a transformative technology. Known for its efficiency, reliability, and versatility, this valve is setting new benchmarks in various applications, from manufacturing to HVAC systems. As industries strive for more advanced solutions, the DC Low Voltage Electrical Magnetic Solenoid Valve stands out for its ability to provide precise control with minimal power consumption.

The DC Low Voltage Electrical Magnetic Solenoid Valve is designed to operate with low voltage electrical systems, making it ideal for applications where energy efficiency is crucial. By operating on a low voltage, the valve minimizes power consumption while delivering effective performance. This energy-efficient operation not only reduces operational costs but also aligns with the growing emphasis on sustainable practices. The valve’s ability to function efficiently at low voltages makes it a preferred choice for modern control systems seeking to balance performance and energy use.

One of the standout features of the DC Low Voltage Electrical Magnetic Solenoid Valve is its precision control. The valve utilizes advanced magnetic solenoid technology to regulate the flow of fluids or gases with high accuracy. This precise control is essential in various applications, including automation systems, irrigation, and HVAC systems. The valve’s ability to make fine adjustments based on control signals ensures performance and reliability, contributing to the smooth operation of complex systems.

Reliability is a critical factor in industrial and commercial applications, and the DC Low Voltage Electrical Magnetic Solenoid Valve excels in this regard. Its robust construction and high-quality materials ensure long-term durability, even in demanding environments. The valve’s design minimizes the risk of mechanical failure, reducing the need for frequent maintenance and repairs. By providing consistent and dependable performance, the DC Low Voltage Electrical Magnetic Solenoid Valve helps enhance overall system reliability, to fewer disruptions and increased operational efficiency.

The versatility of the DC Low Voltage Electrical Magnetic Solenoid Valve makes it suitable for a wide range of applications. In manufacturing, the valve can be used to control the flow of liquids or gases in production processes, ensuring accuracy and efficiency. In HVAC systems, it regulates airflow and temperature, contributing to improved climate control and energy savings. Additionally, the valve’s adaptability makes it an choice for irrigation systems, where precise water flow control is essential for optimizing crop growth and resource management.

As industries increasingly focus on sustainability, the DC Low Voltage Electrical Magnetic Solenoid Valve supports green initiatives through its energy-efficient design. By operating on low voltage, the valve reduces overall energy consumption, aligning with efforts to minimize environmental impact. Its efficient performance also contributes to reduced carbon emissions, supporting broader sustainability goals. Facilities that incorporate this valve into their systems can demonstrate their commitment to environmental stewardship while benefiting from lower energy costs.

The DC Low Voltage Electrical Magnetic Solenoid Valve is designed for ease of installation and maintenance. Its compact and user-friendly design allows for straightforward integration into existing systems, minimizing installation time and complexity. Additionally, the valve’s durable construction and accessible components simplify maintenance procedures, reducing downtime and operational disruptions. This ease of maintenance contributes to the valve’s cost-effectiveness, making it a practical choice for various applications.

The development of the DC Low Voltage Electrical Magnetic Solenoid Valve reflects broader trends in control technology, where precision and efficiency are increasingly prioritized. As industries seek more advanced solutions, the valve’s ability to provide accurate control with minimal power consumption positions it as a key component in modern systems. Its integration with low voltage electrical systems aligns with the ongoing evolution of smart technologies and automated control processes.

EN

EN English

English Español

Español